|

|

|

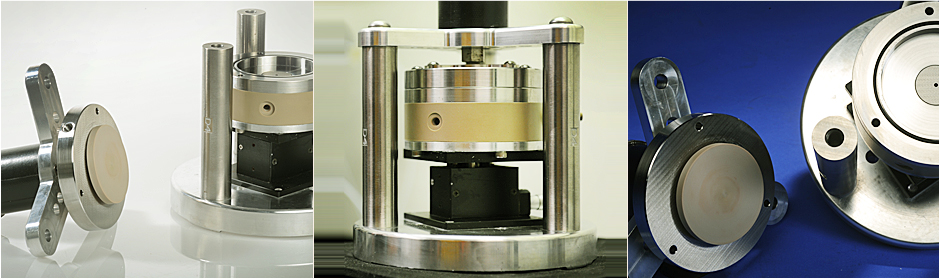

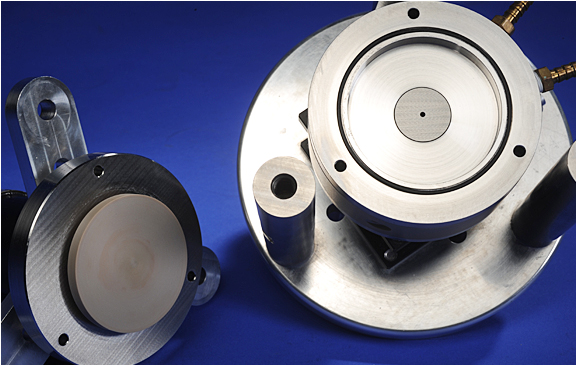

The SynthetronTM technology platform is characterized by reactors that provide severe cross-shearing of thin films of continuously flowing reagent streams. This ensures complete molecular scale mixing with concurrent elimination of mass transfer limitations. This flow chemistry approach enables production speed increases and efficiency improvements that are unparalleled over alternative processing methods.

SynthetronTM processes are continuous and typically require reaction volumes of less than 0.25 mL utilizing residence times of only fractions of a second. Continuous operation facilitates scale-up and we have found most often our systems are capable of producing multi-kilogram quantities of product in less than one hour.

KinetiChem’s reactor technology rapidly and intensely mixes solutions to increase the molecular collision frequency. Increasing the collision frequency, while holding all other reaction parameters constant, ultimately provides for an improved observed reaction rate. In continuous flow operation, this translates to higher throughputs with a smaller device footprint. In addition to significantly increasing the frequency of molecular collisions, the use of higher reagent stream concentrations in conjunction with a large surface area to solution ratio, enables a scientist using KinetiChem’s reactor platform to fine tune a great number of options in an effort to positively impact an observed reaction rate, which ultimately relates to speed and ease of scalability. One academic user of KinetiChem’s reactor technology has observed the product of a reaction appearing thousands of times faster than with conventional processing methods. Using our S3T1 reactor system they produced the desired reaction product in a matter of seconds of reaction time compared to a traditional stirred tank process where the product was unobservable after 6 hours of reaction time (Fuel, 2011, 90, 898–901)! Early explorations of some other more typical fine-chemical processes have demonstrated the capabilities of producing multiple kilograms per hour with the use of less than 0.2 mL of reaction volume, ultimately conducting reaction processes with a reaction zone residence time of less than one tenth of a second.

The same Synthetron S3T1 reactor has been shown to be effective at providing residence times of tens of seconds, to tenths of a second (Fuel, 2011, 90, 898–901), up to times less than 0.01 seconds (Tetrahedron Letters, 2010, 51, 4793–4796) at flow rates of over 400 mL/min, ultimately handling a wide range of effective flow rates.

In addition to broad flow rate flexibility and production output, Synthetron systems are designed to be easy to operate and clean for a broad number of reaction conditions. Handling precipitate formations, gas-liquid reactions, and a variety of reaction types, the Synthetron is truly a flexible and rapidly scalable platform any serious flow chemistry scientist should maintain in their arsenal.

In one example, the SynthetronTM reactor system has improved the yield of a batch reaction from 57% to 96% while only requiring less than one day of optimization efforts! Among others, the following reaction classes have been dramatically impacted through their adaptation to the SynthetronTM reactor platform:

From milligrams to multiple kilos per hour ON THE SAME SYSTEM!

|

|

For more information about our reactor systems and how you can begin utilizing them,

please fill out our contact form or call us at 845-536-4244

- Home

- |

- TECHNOLOGY

- |

- About US

- |

- Contact US

©Copyright © 2011, KinetiChem, Inc. All Rights Reserved

Los Angeles Web Design by Altadar